We build tomorrow’s high value oil and gas solutions with innovation, efficiency, and a focus on environment.

...Beyond Brilliant™

FIVE REASONS CARDIUM/CHARLIE LAKE DRILLERS SHOULD GO PAD-FREE

Introduction

The shale industry, especially in the United States and Canada, has revolutionized the global oil and gas markets by tapping into previously inaccessible resources through technologies like hydraulic fracturing and horizontal drilling. However, it faces several challenges, particularly regarding costs, environmental, market, and operational concerns. While there are a number of initiatives being implemented, such as extended reach laterals, there are also drawbacks and limitations concerning limited runway for drilling up Tier 1 and Tier 2 acreage positions. For that reason, as well as environmental issues, the next wave of technology could very well be Pad-Free™ Drilling, utilizing multilateral wells combined with multistage fracturing in a variety of reservoirs.

As oil and gas operators have become more sophisticated and data-driven optimization continues to advance, certain limits may have been reached. Emerging challenges suggest a need for a transformative approach to extraction. This article presents five key reasons why operators in Canada’s Cardium and Charlie Lake formations should consider adopting multilateral wells with Pad-Free™ Drilling. We’ll explore each reason in depth, outlining how this approach can address production challenges, meet emissions reduction targets, and drive a significant shift in drilling and production strategies.

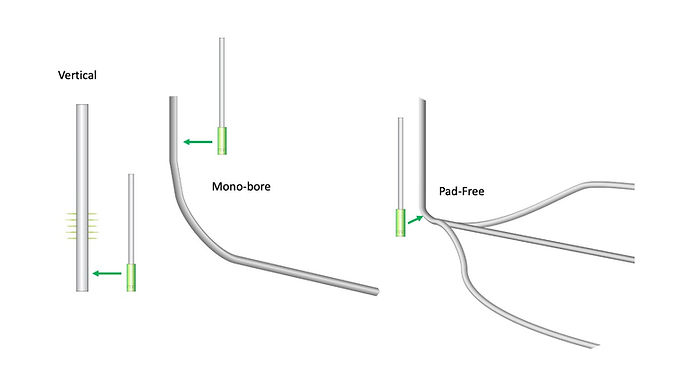

Figure 1 - Rokk's Pad-Free drilling and completion systems can replace multiple wells improving economic and environmental performance.

REASON 1 – IMPROVED DRAWDOWN AND INCREASED ULTIMATE RECOVERIES

Historically, oil and gas wells have been drilled and produced vertically. Producing was simple as operators set casing through and below the producing zone and, during production, were able to place the pump below the perforations. This provided excellent gas separation and unlimited drawdown. In fact, it was possible to get drawdown at the perforations very close to zero by controlling the fluid level.

Compared to vertical wells, pumping oil from horizontal wells presents unique challenges due to the well’s extended lateral section and complex flow dynamics. Issues such as multi-phase flow, gas locking and solids transport are further complicated due to current practices using mono-bore well design with small diameter casings (4-1/2” – 114.3mm). This now creates two major producing issues. First, the well design combined with small diameter casing prevents operators from being able to “sump the pump” and in fact, operators will typically place a pump significantly high in the well causing high back pressure. This is primarily due to the horizontal build section and the inability to design a profile that will allow pump placement to be low in the well. High pump placement leads to high back pressure that limits inflow and drawdown. The second issue is related to limitations on gas separation and solids control. Both can prove difficult in smaller casing and can lead to issues such as gas-locking and increased rod wear, resulting in significantly higher operating costs and reduced operational efficiency.

Figure 2 - One of the key benefits of Pad-Free Drilling can be increasing recoveries while reducing lift costs during the life of the well. Monobore well design can be particularly challenging.

Key factors affecting drawdown and the challenges that need to be addressed include pump placement, gas separation, managing sand and solids, limitations of alternative lift methods (such as ESP, gas lift, and plunger lift), and the generally high back pressure that restricts liquids production. The high costs associated with addressing these issues in very small casing present a significant challenge, particularly on multi-well pads. In many cases, solutions to these problems can become cost-prohibitive. However, it has been shown throughout basins in North America that lowering the fluid level of a well continues to be one of the key factors in increasing recovery. What if we could solve the drawdown challenge by moving to multilateral wells, including three legs and 6 miles of reservoir contact?

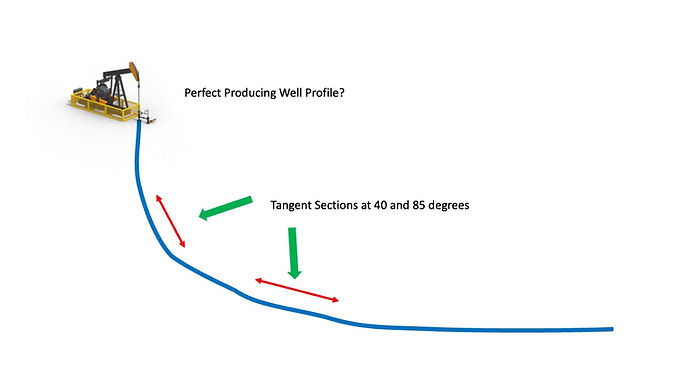

If the cost of “effective lift design” can be distributed across multiple laterals in a single well, then both the cost and the attention to design become workable. In fact, it may totally change the approach to artificial lift. Adding enhanced data and machine learning would be possible. Speaking to industry experts, there may be an optimum or “perfect well profile” to lower drilling costs but also to reduce lift costs and improve production and ultimate recovery for the life of a well.

REASON 2 – REDUCE PER-METER WELL COSTS

To date, the industry has primarily used extended reach laterals (generally 2-mile and now approaching 4-mile laterals in some areas) to reduce per-meter cost while burning through much of the high-graded (Tier 1 and Tier 2) inventory. Although it is an effective method to reduce per-meter cost, it comes at the price of significantly diminishing recovery. Most of the data from various studies (SPE, technical articles) indicate as follows: If the 1st mile is 100% recovery, the 2nd mile is typically 60% of the 1st mile. The industry typically calls this an 80% effective well, but giving up 40% of what is easily recovered might be a questionable practice. The recovery factor diminishes even further for 3-mile laterals, which recent studies have shown drops to 40% of the 1st mile. The focus on payout and economics is good, but if an operator is burning through the best-remaining acreage, this may not be a good option for long-term operations.

Figure 3 - Pad-Free Drilling can significantly reduce lift costs over the life of the well by reducing pump requirements, improving the well profile, enhancing drawdown, and optimizing gas separation.

The good news is that many of the drilling challenges have been successfully addressed, but costs during completion and production for long lateral wells continue to be a challenge. In addition, as operators chase longer and longer laterals, effective stimulation and production may prove difficult and expensive. In theory, fracing is supposed to create a large, well-connected, stimulated reservoir volume around the wellbore. In practice, however, the SRV is often limited and does not extend far into the rock, leading to low recovery factors as a smaller fraction of the hydrocarbons near the toe of the well are produced in long lateral wells.

Automating repetitive tasks and adopting advanced data analytics for better decision-making can reduce costs. The industry has moved quickly to adopt machine learning and automated drilling, instituting downward pressure on pricing throughout the service industry and supply chain. However, further declines in service costs are unlikely in an inflationary economy with an already cash-starved service industry.

Moving to multilateral wells with multistage hydraulic fracturing could provide considerable running room for further cost reduction. Industry discussions have provided the following cost guidance after conducting an analysis. Moving from two separate wells to a dual-leg Pad-Free™ multilateral well can reduce per-meter development costs by 20%. Furthermore, it is estimated that moving to three-leg wells with a similar approach could reduce development costs by 30% to 40%. In addition, gains may be seen from improved drawdown and reduced lift maintenance costs over the life of the well. Experts estimate that major cost reduction, as well as reduced environmental impacts, will be substantial. Significant short-term cost reductions should be seen in well construction and perhaps stimulation.

REASON 3 – MAXIMIZE EFFECTIVE RESERVOIR CONTACT

Maximum Reservoir Contact (MRC) wells are an advanced type of well design aimed at maximizing the exposure of the wellbore to the reservoir, thereby increasing the production potential and overall recovery from a given formation. MRC wells achieve this by using complex drilling techniques to extend the wellbore in multiple directions within the reservoir, creating a network of branches or laterals that greatly increase the reservoir contact area compared to conventional wells. Historically, these have been applied in conventional reservoirs that do not require hydraulic fracturing or complex completion methodologies. However, the largest future target for MRC wells will be unconventional wells, provided that completion capabilities such as hydraulic fracturing are available.

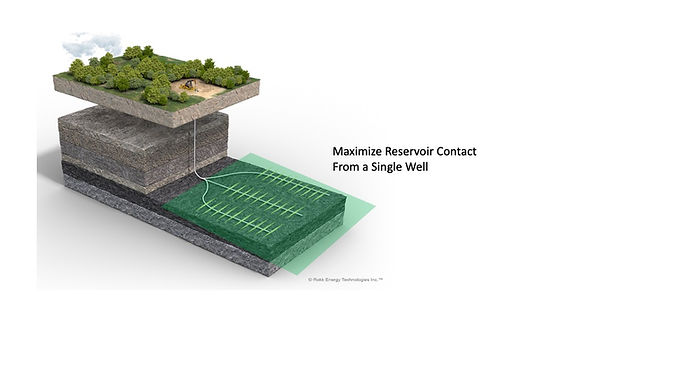

Figure 4 - MRC well design using Pad-Free Drilling technology could provide 6 miles of reservoir contact, all with multistage fracturing.

In current MRC wells in shale (long lateral producing wells), we have seen declining effectiveness as lateral length increases. During production, the pressure gradient decreases along the length of the wellbore, which can result in less effective production at the far end of the well. This issue, often referred to as "heel-to-toe" pressure differential, means that much of the production comes from the part of the well closest to the entry point, leaving hydrocarbons further along the lateral harder to extract. In addition, increasing gas-oil ratios (GORs) will further complicate the problem. What is the next possible solution? Theoretically, it might be possible to drill and produce more effective 3-mile lateral exposure wells using three 1-mile laterals branching from the same mainbore. This could produce 100% effectiveness on all three laterals in comparison to a single 3-mile lateral. If an operator is comfortable with 2-mile laterals (80% recovery), then drilling multilateral wells with three 2-mile laterals could also be a very effective solution. In essence, this could provide 6 miles of lateral exposure, complete with hydraulic fracturing, and allow a variety of fracturing methodologies due to the shorter length of lateral.

One additional benefit could be that in the later life of wells, accessing a one-mile or two-mile lateral becomes economically feasible. These wells now become attractive candidates for enhanced recovery or refracturing, as advances in technology improve. In any case, six miles of lateral exposure is not even “on the radar” for most companies as they struggle to get the third mile to produce successful economic recovery volumes compared to shorter wells. Pad-Free™ Drilling may be suitable for many of the current reservoirs, particularly for Cardium, Charlie Lake, and high-liquids Montney in Canada, and could provide both three-mile and six-mile MRC well designs that may also offer benefits for improved artificial lift, as discussed earlier.

REASON 4 – REDUCED LIFT COSTS FOR THE LIFE OF THE WELL

Reducing artificial lift costs for horizontal wells is crucial to improving profitability, especially in shale and tight oil plays where operating margins are often narrow. Lift cost, or the costs associated with lifting oil and gas from the reservoir to the surface can be significant. Given the fact that most wells have increasing GOR’s (gas-oil ratios) during their producing life, it may become more challenging over time. There are several strategies to help lower lift costs for horizontal wells, but the current mono-bore well design presents a significant challenge to implementation. Issues with reduced casing diameter may prove technically challenging and cost-prohibitive in achieving a reduction in lift costs.

Figure 5 - It is possible to greatly improve production efficiency and ultimate recovery through the enhancement of artificial lift. Although the industry has focused on reducing costs, the long-term value could be provided by building the “perfect well profile”

Moving to Pad-Free™ well-design changes all of that. Although the design of the well requires setting intermediate casing, the upsizing of the intermediate casing provides significant benefits. It may be possible to design the “perfect well profile” that will improve drawdown, reduce issues with sand and solids, and eliminate gas-locking. It also reduces the total number of wells and allows an operator to focus on the operable design for a single well with three laterals rather than three separate wells that each require attention to artificial lift. This will become increasingly important later in the life of a well as the gas percentage increases.

Pad-Free™ multilateral design can reduce a six-well pad to two wells while maintaining the same amount of lateral exposure. Thus, it can reduce lift and operating costs by more than 65% and allow for the replacement of inefficient lift methodologies. For example, instead of installing six-rod pumps, an operator may be able to install two ESP pumps, have adequate gas separation, and achieve excellent efficiency. It is also possible to add enhanced data to provide improved control over drawdown and significantly increase ultimate reservoir recovery over time.

REASON 5 – REDUCE EMISSIONS AND SURFACE IMPACT

Emissions reduction in oil and gas well drilling and production are increasingly important as the industry seeks to meet stricter environmental regulations, respond to investor pressure, and reduce its overall carbon footprint. The primary goal is to decrease greenhouse gas (GHG) emissions—mainly carbon dioxide (CO₂) and methane (CH₄)—throughout the drilling, completion and production phases. Emissions reduction strategies encompass a variety of approaches, from optimizing drilling and completion techniques to adopting cleaner energy sources and reducing flaring and venting. Production from shale wells involves significant sources of emissions, including methane leaks, flaring, energy-intensive artificial lift systems, and transportation of produced water and oil.

Multilateral well designs can effectively reduce emissions by consolidating multiple producing laterals into a single wellbore, thereby minimizing surface disturbance, infrastructure requirements, drilling energy, and material use. As energy companies increasingly prioritize sustainability, multilateral wells provide an efficient means of accessing resources while lowering the carbon footprint associated with production activities. A major source of emissions and methane release tends to be producing oil or high-liquids wells and associated production equipment, such as pumps and stuffing boxes. Ideally, an operator would want to consolidate or perhaps change artificial lift methodologies.

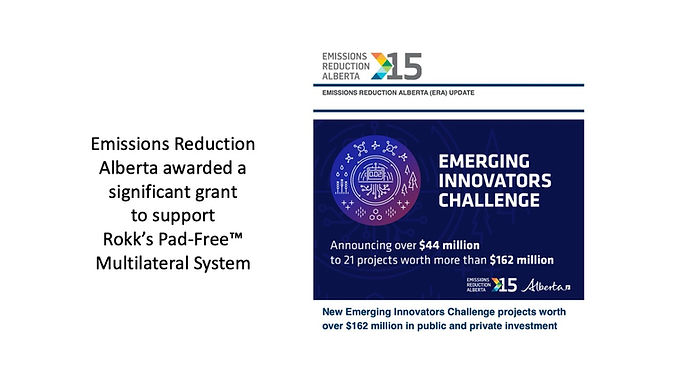

Figure 6 - Rokk’s Pad-Free multilateral technology has been awarded a grant by Emissions Reduction Alberta, and can have a significant impact on moving toward the federal government’s emission goals.

Pad-Free™ well design will allow consolidation from three individual wells into a single producing well. Not only does this provide an immediate 65% reduction in emissions due to the reduction of surface emission sources, but it may also allow a total change in approach from artificial lift. For example, in a Cardium or Charlie Lake producing oil well, it may be possible to change a six-well pad into two wells with three laterals in each well. This provides an immediate reduction in both surface impact and in points of potential methane emissions by two-thirds. In addition, drilling the “perfect well profile” for production may allow further increases in ultimate recovery. Also, it might be possible to completely replace rod pumping with electric submersible pumps that may be viable for years instead of months in the producing life of the well. Machine learning and enhanced data analysis may also be possible due to better pressure and optimization information.

We have seen a desire from regulatory bodies as well as landowners to reduce surface impact significantly. Thus, the ability to potentially remove surface pump-jacks in favour of ESP pumping may be extremely favourable. In addition, 6 miles of reservoir exposure (3 laterals x 2-mile length) can also significantly improve the economics of both drilling and long-term production.